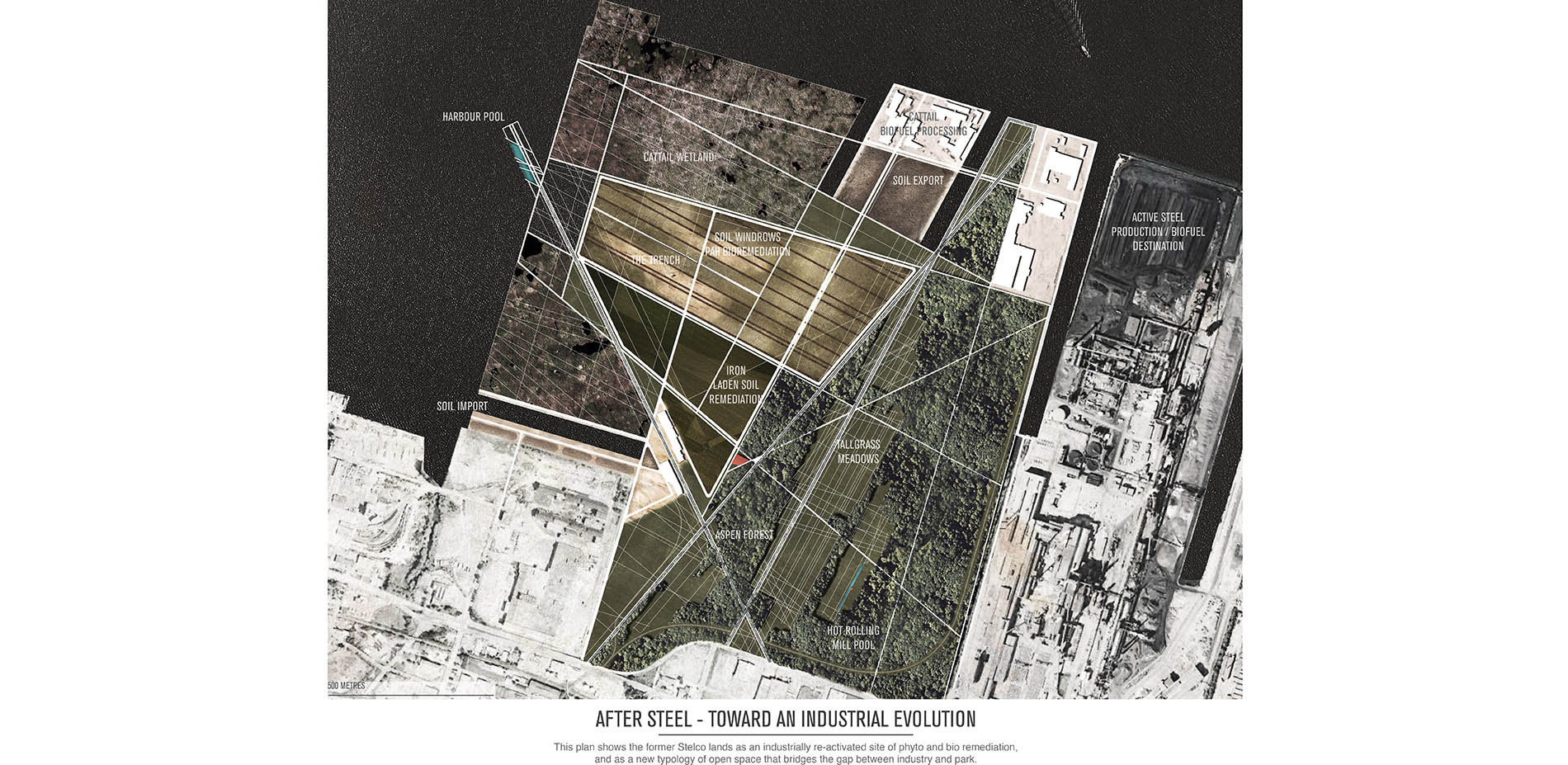

AFTER STEEL - TOWARD AN INDUSTRIAL EVOLUTION

This plan shows the former Stelco lands as an industrially re-activated site of phyto and bio remediation, and as a new typology of open space that bridges the gap between industry and park.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

COLLAPSING INDUSTRIES - SHRINKING CITIES

Manufacturing decline can be observed in cities across Canada. Hamilton, Ontario, has experienced dramatic decline in recent years, where the collapse of the steel industry on the former Stelco lands has left 895 acres of contaminated lands open for re-imagination.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

ON THE EDGE OF COLLAPSE

The site exists on the edge of the city and projects into Hamilton Harbour. Created largely on fill, the site has grown away from the city and has resulted in an edge condition that has little interaction with its surroundings.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

RELATIONSHIP OF SITE TO CITY

In the community, the impact of the site is largely visual, rather than physical, existing as a monolithic form on the skyline. The only way to grasp the scale of the site is to view it from great distances.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

FROM EXTRACTION TO EXPORT - MAPPING MATERIAL FLOWS

Although Hamilton is known as the source of steel, the raw materials that feed the large ovens is imported from mines from around the Great Lakes and across the country. This analysis exposes the true scale of the operations.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

LOCAL PRODUCTION

Once on site, the raw materials are exposed to massive amounts of heat and energy, which takes materials like coal, iron and limestone and turns them into products for export but also waste for disposal.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

GLOBAL CONSUMPTION

At one time, Hamilton was the largest steel producer in Canada, and its products were shipped globally to meet a world wide demand.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

CURRENT SITUATION: A REPULSION OF NATURAL SYSTEMS

As the site grew from the 1880s to present time, it filled in nearly one quarter of the harbour and pushed all natural systems away. The site also contributed to Randle Reef, one of the most polluted sites in Canada.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

FROM WASTE PRODUCTION TO WASTE CONSUMPTION

The fundamental basis of this project is a shift in material flows, moving the site from one of resource consumption and waste production, to one where waste becomes the resource that fuels the creation of new products and resources.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

FROM MATERIAL FLOWS TO SITE DESIGN

Each new waste flow is used to generate a specific design element, generated by the needs and results of related processes. These elements shape the form of the site and frame new interactions with the city and its residents.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

CATALYZING A REGIONAL GREEN NETWORK

By following a phased approach to implementation, the goal of this design is to become a catalyst for a new green network, reconnecting the Niagara Escarpment to the harbour, and connecting trail networks across the city.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

HARBOUR POOL

The Harbour Pool creates a safe space to swim “in” Hamilton Harbour, directly above one of Canada’s most polluted sites. This ironic situation, swimming in a pool in the lake, exposes the community to the unseen realities of the site.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

THE TRENCH

The Trench is a 15-metre deep cut into the landscape, from the surface down to the original lakebed. By descending down this path, people are consumed by the enormity of the fill operations that took place over the past century.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.

HOT ROLLING MILL POOL

The Hot Rolling Mill Pool is an artificial hot spring, heated using waste heat from the active steel furnaces on the adjacent site. This creates a situation where people are comforted and warmed by the industrial scale burning of coal.

Photo Credit: Robert McIntosh

Media: Please submit high-resolution image requests to images@asla.org.