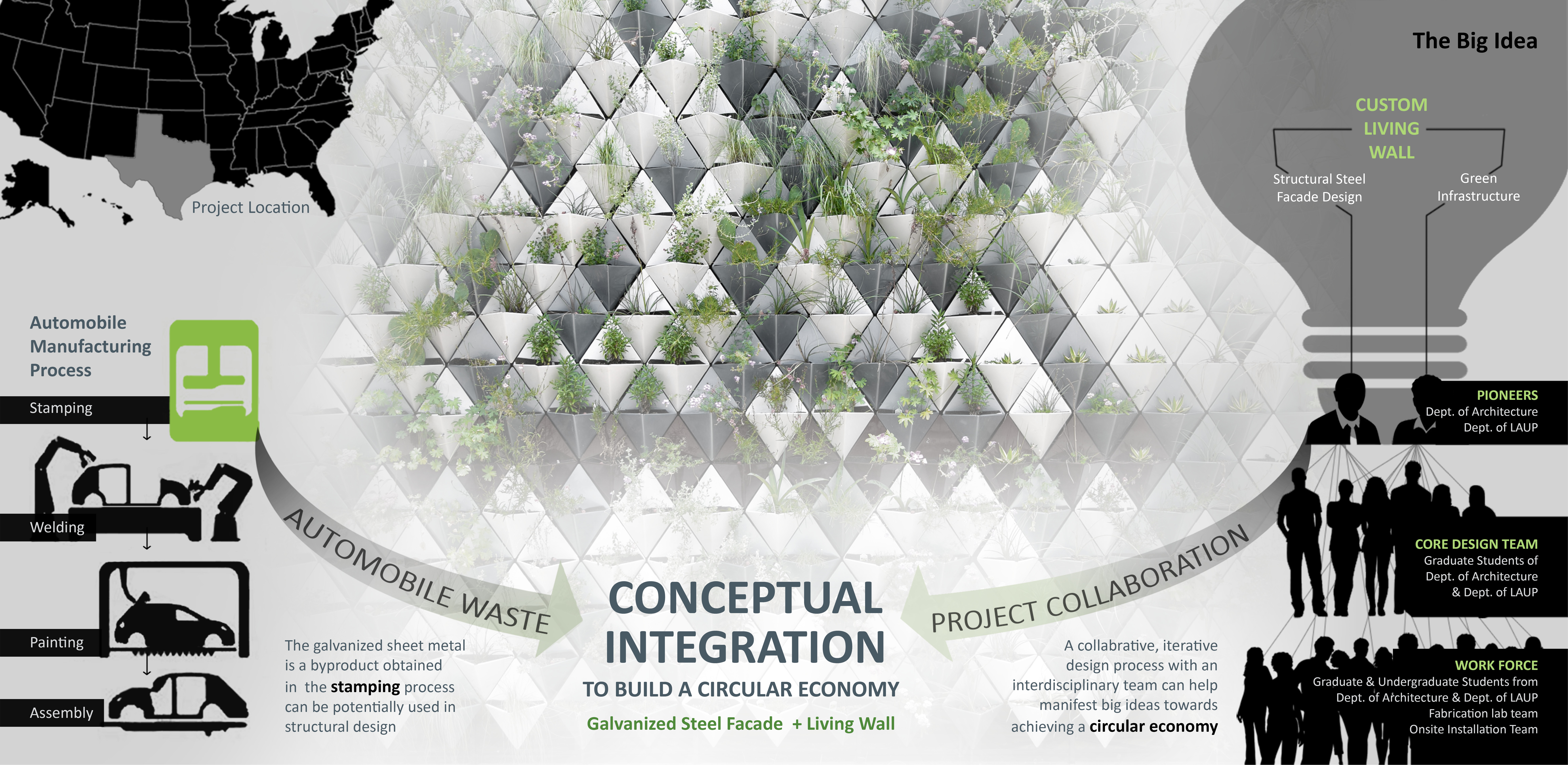

Custom Living Wall from Industrial Waste-stream

Honor Award

Student Collaboration

Haoyue Yang, Student ASLA; Panwang Huo; Niti Tataria, Student ASLA; Karishma Joshi, Student ASLA; Yuanjia Yang, Student ASLA; Yu Shi, Student ASLA

Faculty Advisors: Bruce Dvorak; Ahmed Ali

Texas A&M Univeristy

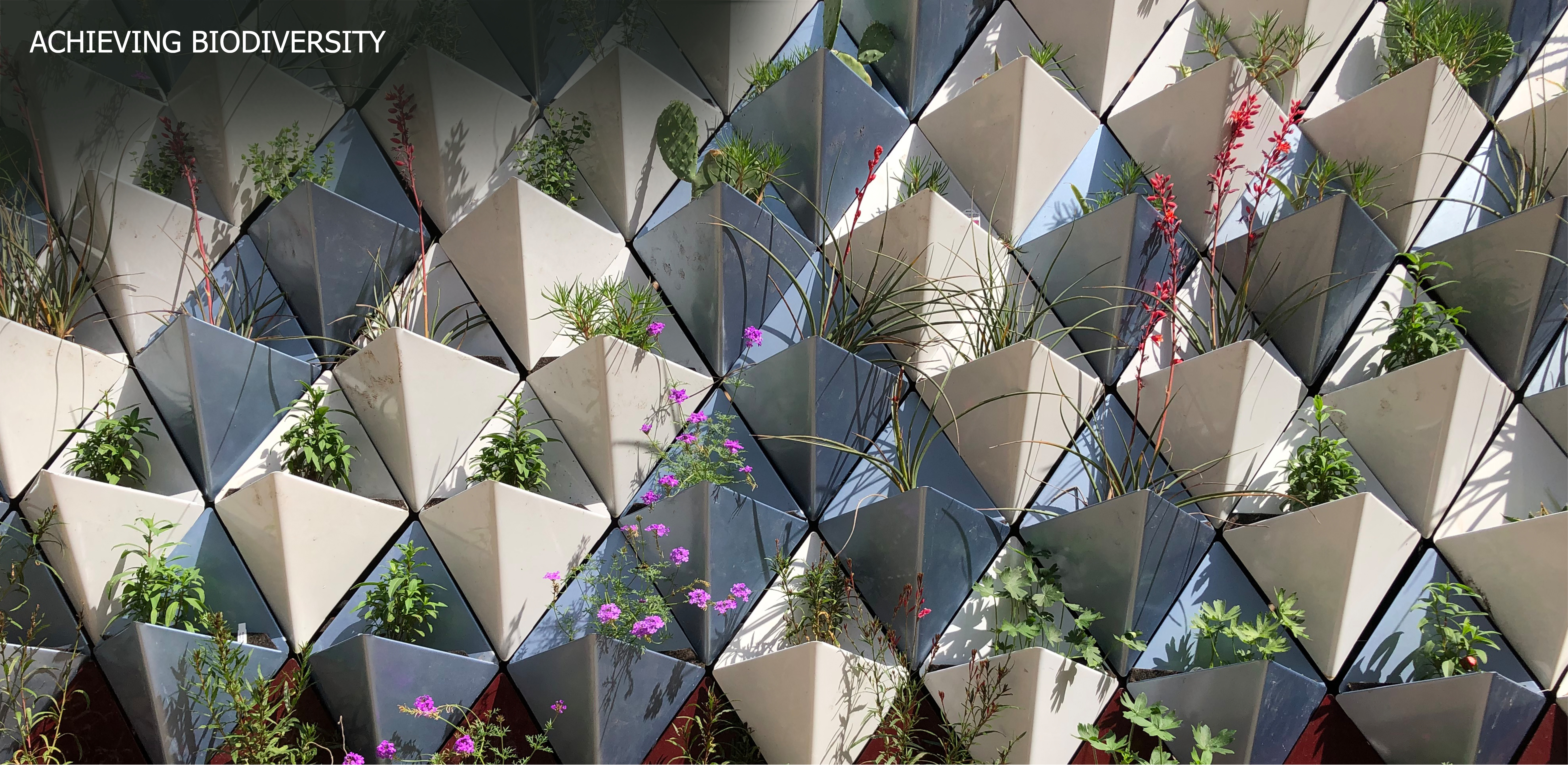

A multi-year, cross-disciplinary process led to the development of a galvanized steel living wall system, as well as the potential for a circular economy that transforms industrial waste into green infrastructure while enlivening a blank wall. Automotive sheet metal scraps become inverted pyramids that form a flexible façade garden; individually demountable units allow discrete control and modulation of watering, soil maintenance, and plant health. Extensive study of plant performance across eighteen species, paint performance as related to heat gain, and comparisons to existing wall systems resulted in a diverse micro-scaled ecosystem that welcomes pollinators to a new focal point.

- 2020 Awards Jury

Project Credits

M.Arch, Student Helper

Michael Irving

M.Arch, Student Helper

Yiming Du

BLA, Student Helper

Louis Birdsong

MLA, Student Helper

Lingyu Kong

MLA, Student Helper

Yanzi Zhao

MLA, Student Helper

Yinghui Chen

MLA, Student Helper

Shen-Yu

PhD Arch, Student Helper

Patricia Kio

Fabrication Support

Fabrication Lab at Texas A&M University, College of Architecture

Onsite Installation Support

SSC Services for Education

Materiel Supply

General Motors, Flint, Michigan

Paint Service

Casey’s Body Shop

Plants Supply

EBR Enterprises - Native Enhancements Division

Assistant Professor, Department of Architecture- Principal Investigator

Dr. Ahmed K. Ali

Project Statement

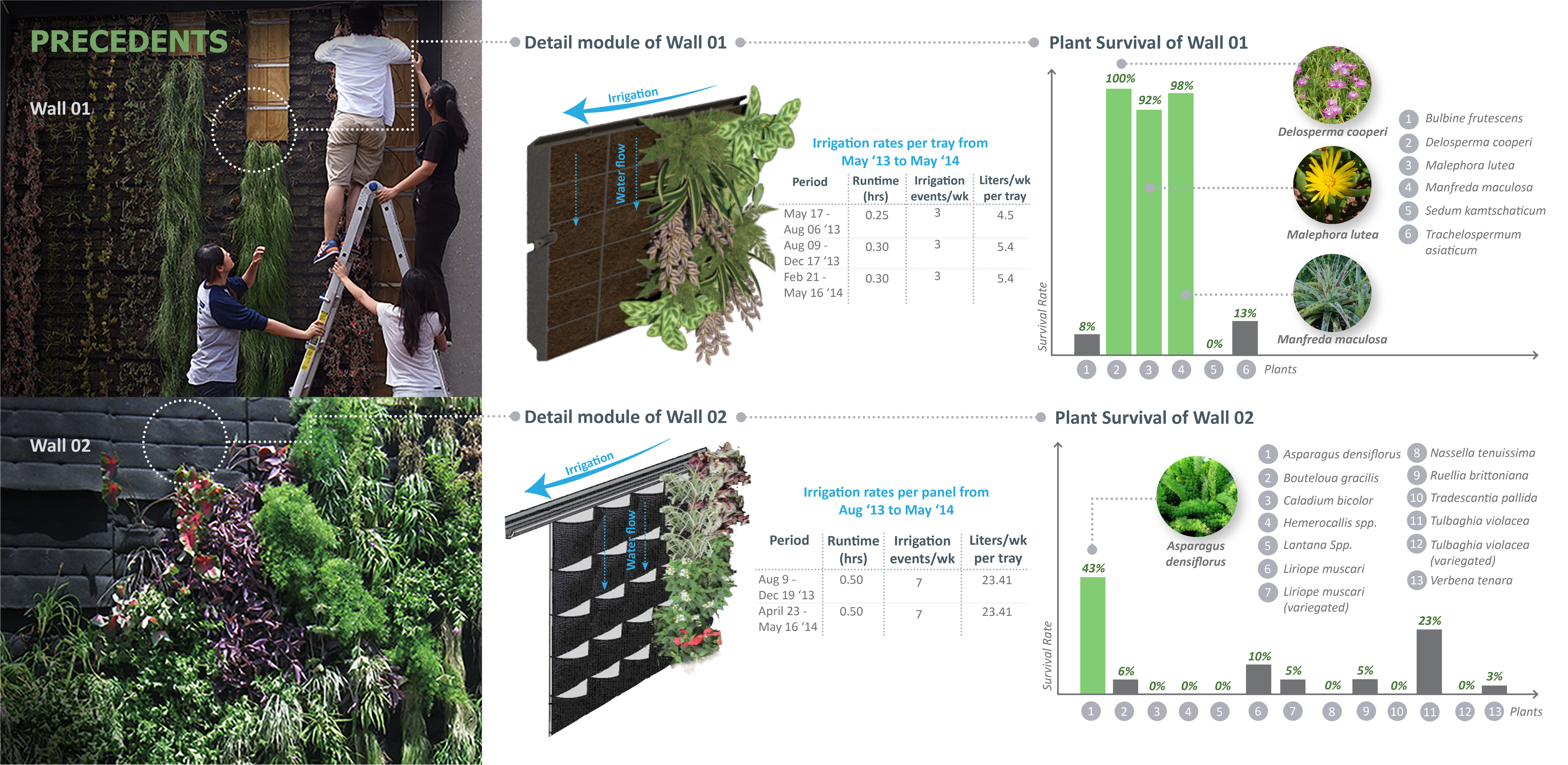

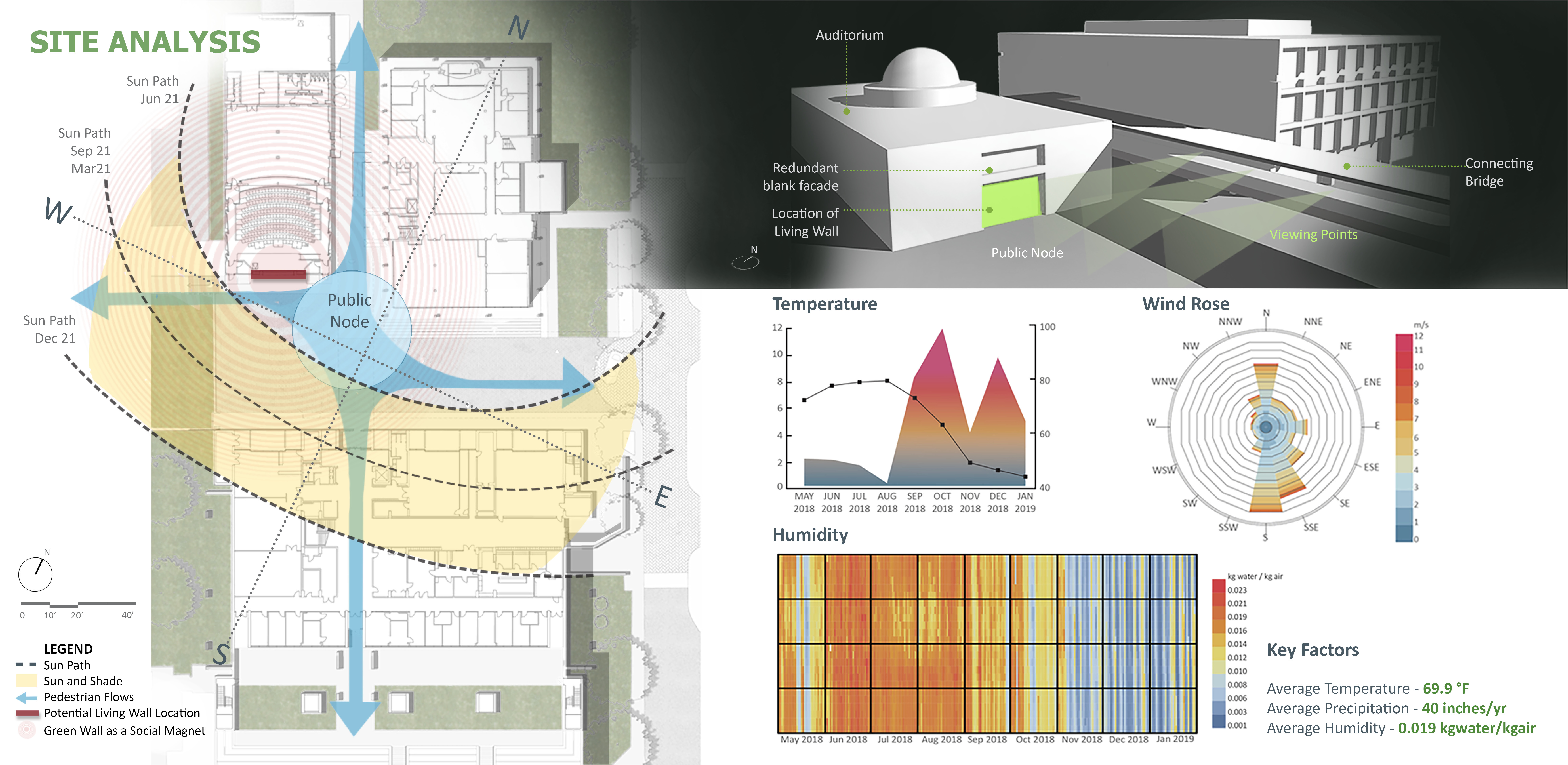

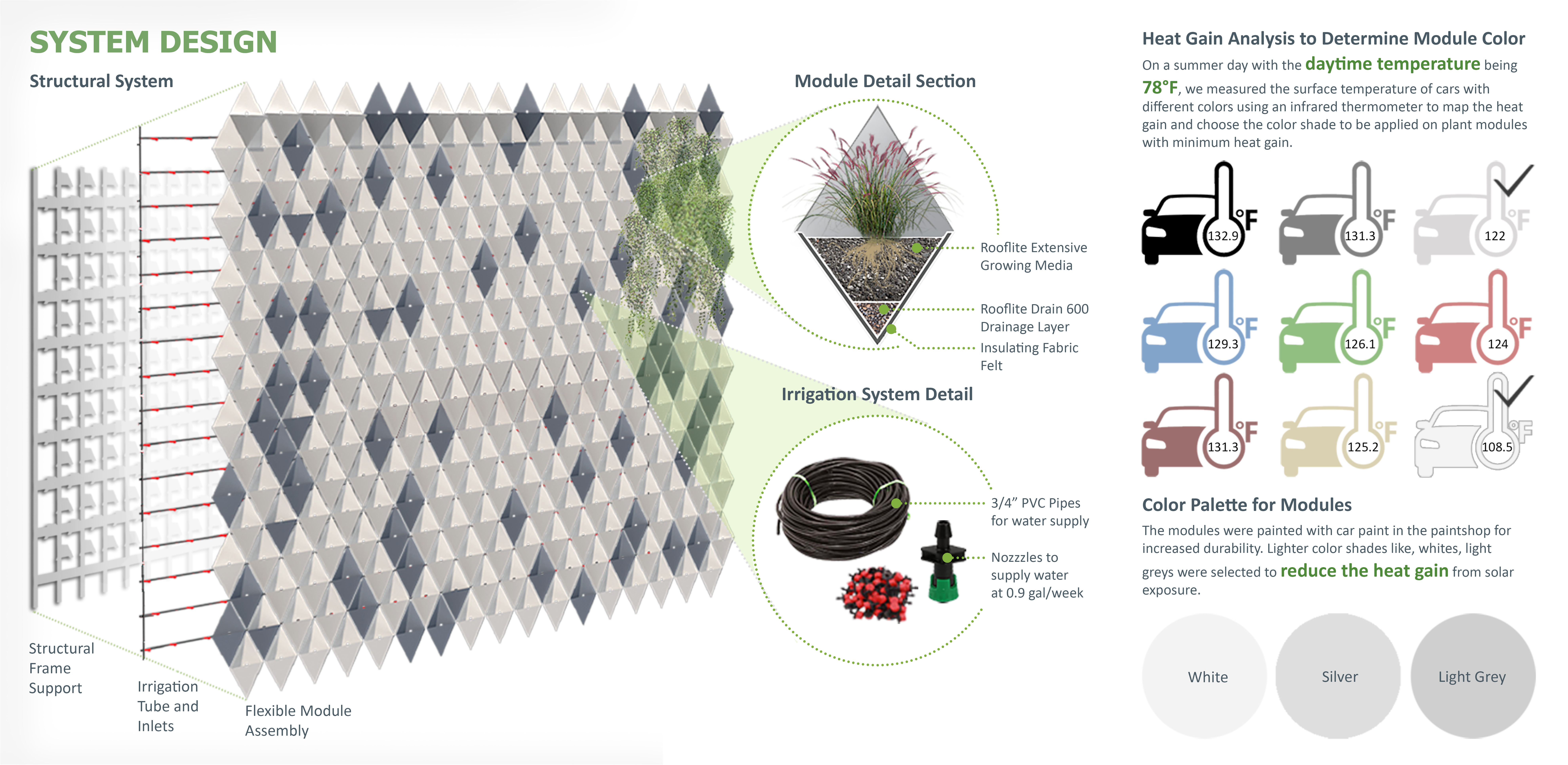

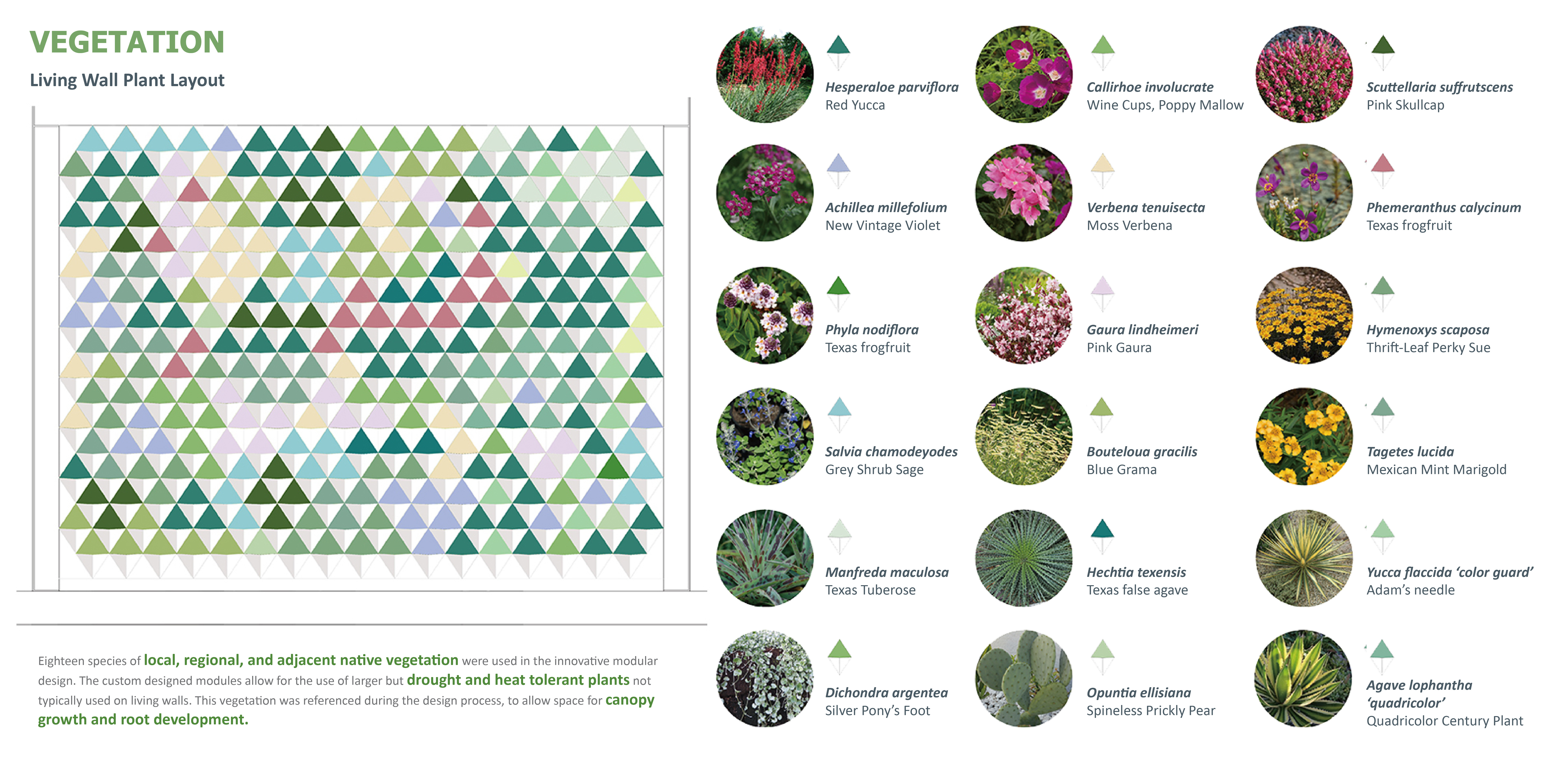

Students in landscape architecture and architecture programs collaborated on this multi-year interdisciplinary project to design, build and evaluate the performance of a custom living wall system. Our aim was to design a living wall system that achieves an optimal microclimate for plants. Built from sheet metal by-products, the wall exemplifies how green infrastructure can support a circular economy, and accommodate native vegetation. Important challenges of this project include its requirement to be a low maintenance system, and adapt to a hot south-facing microclimate. We studied the effects of colors on automobile metal surfaces exposed to sunlight, and the results helped us to design and build modules that reduce heat gain. A steel structural support and hanger system was designed to secure the detachable modules. The diagonal arrangement of modules gave an appropriate vertical space for upright plants to grow. This design (patent pending) has proved successful as it has established 18 species of native and climate-adapted plants, cooled the micro-climate, created an aesthetic appeal, is easy to maintain, and fosters habitat for native wildlife.

Project Narrative

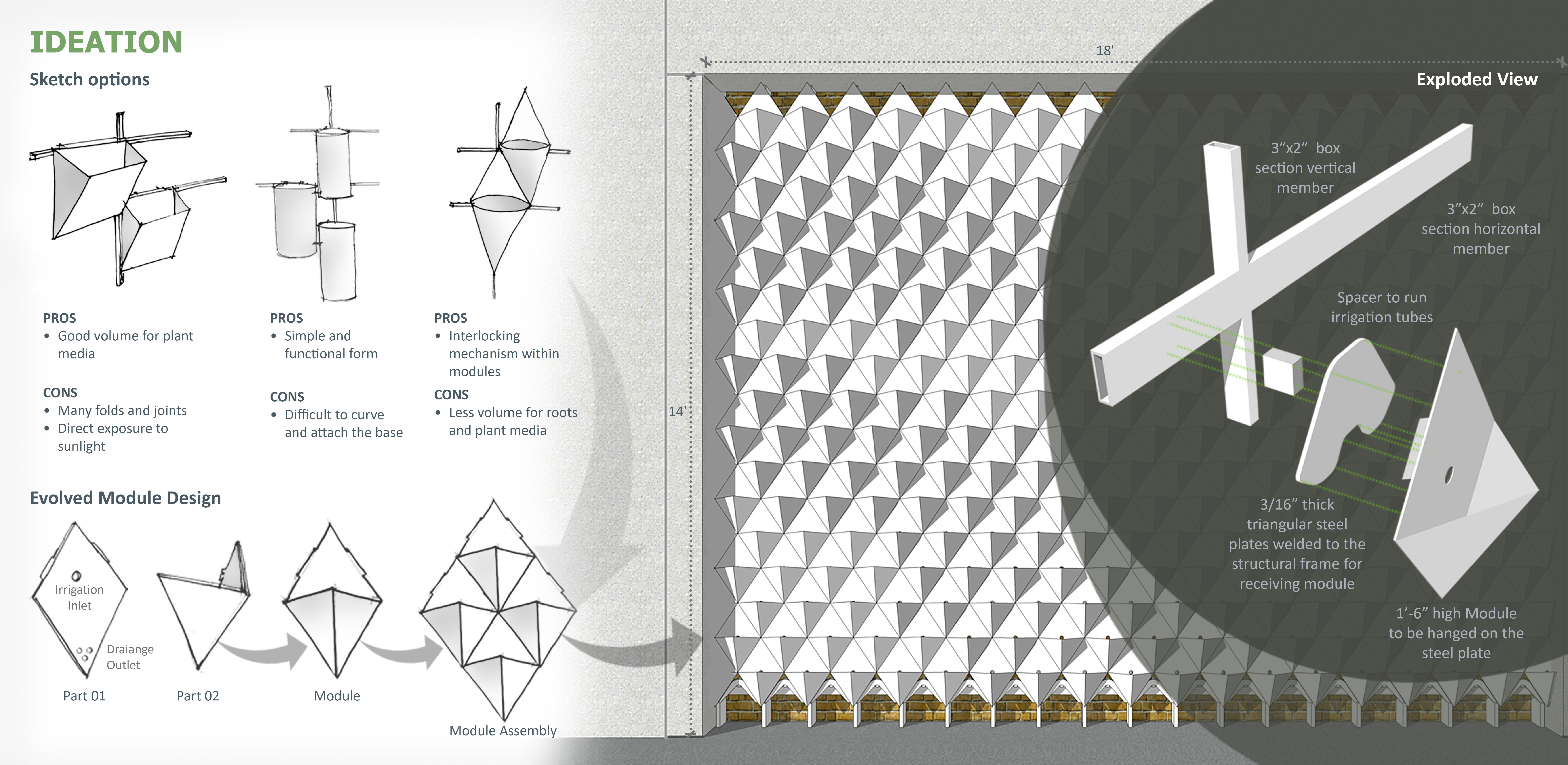

This interdisciplinary project began in Fall 2017, where students from architecture and landscape architecture departments, under the guidance of faculty, collaborated to design a custom living wall system built from scrap metal sheet which is an industrial by-product during automobile production. The fundamental goal of this project was to design, build and evaluate the performance of this custom living wall system to support a circular economy. Driven by lessons learned from on-site research on three vendor-provided systems, this custom design aimed to resolve several limitations of market-based systems. We followed an iterative collaborative approach to answer unique challenges of this project such as a south-facing exposed wall, metal being a primary material and requirement to be a low maintenance living wall system. During the conceptual design phase, we explored different shapes and forms. We studied the effects of colors on automobile metal surfaces exposed to the sun to understand the relationship between color and heat gain. Using a digital infrared thermometer, on a 78.8 ° F, day white paint was 108.5 ° F, and black paint was 132.9 ° F. Our results helped us to propose white and shades of grey that would reduce the percentage of heat gain, as well as the unique pyramidal shape that faces away from direct sunlight. As a result, the custom design (patent pending) allows ample space for plant canopy and root growth, a cooling effect on the microclimate, and a natural upright positioning of plants.

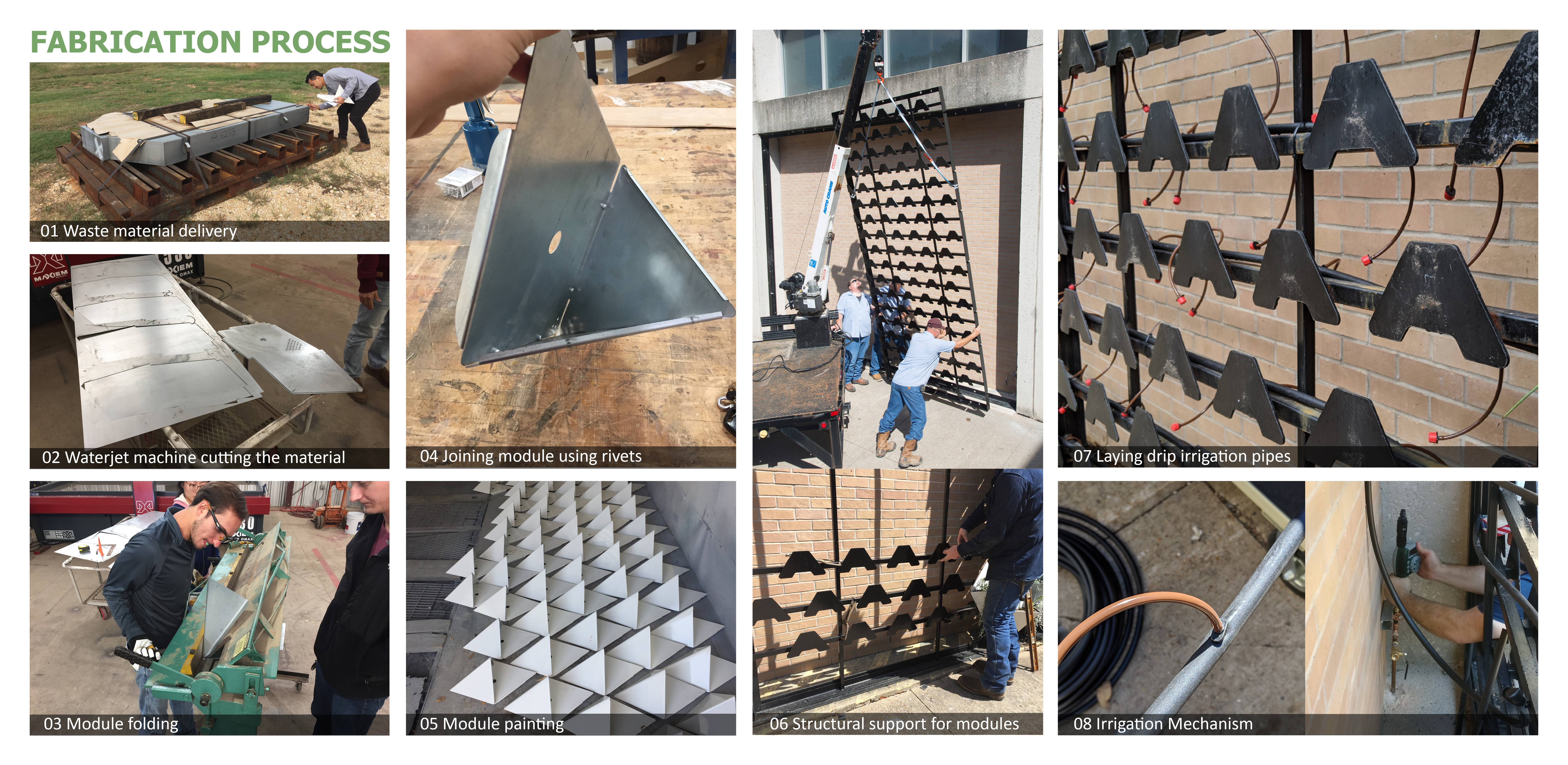

The galvanized sheet metal is a surplus by-product generated by the automotive stamping and blanking operations. These are consistently sized, high-quality pieces of steel that are produced when windows and other spaces are stamped out of body panels on the assembly lines. Because of their consistent size, shape, and quality, these steel pieces are valuable for much more than traditional scrap markets. Offal pieces were between 0.5 to 3.2 mm thick, have various coatings, and total 1,500 metric tons per year. We came up with different design iterations to design the module to accommodate spatial requirements of drought and heat tolerant native plants. The fabrication process was primarily focused on cutting and folding the sheet metal and ensuring that we could have an appropriate volume of planting media. Aesthetics and ease of handling was an important factor that we considered while designing the module. Eventually, the module was designed in two parts which were then riveted together.

The design of the system evolved in order to create an optimal microclimate for plants with the help of drainage, irrigation delivery and plant positioning. The module shape and size were strategically designed to hold maximum soil volume. Each module has provisions for individual irrigation inlets and drainage. A steel structural support system was designed that holds the modules and supports the drip irrigation system behind the modules. The diagonal arrangement of modules gave an appropriate vertical space to grow for upright plants like Red Yucca. Living walls can play an important role to improve urban microclimates; however, they may face limitations especially in extreme hot and cold climates. The selection of plants is critical in the success of living walls. Studying the work of previous research on plants for living walls on campus, we experimented with primarily drought-tolerant, native and adaptive plants.

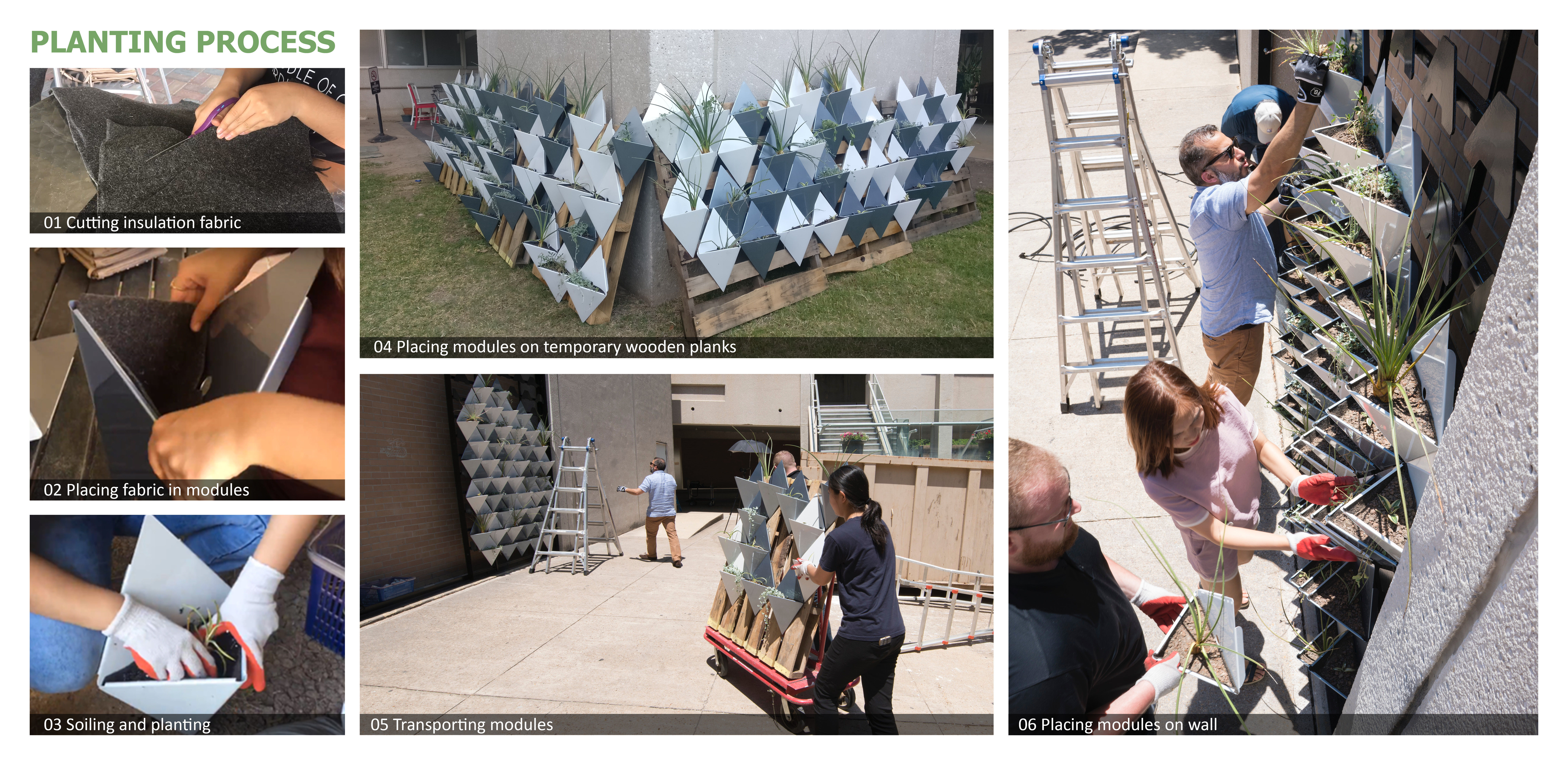

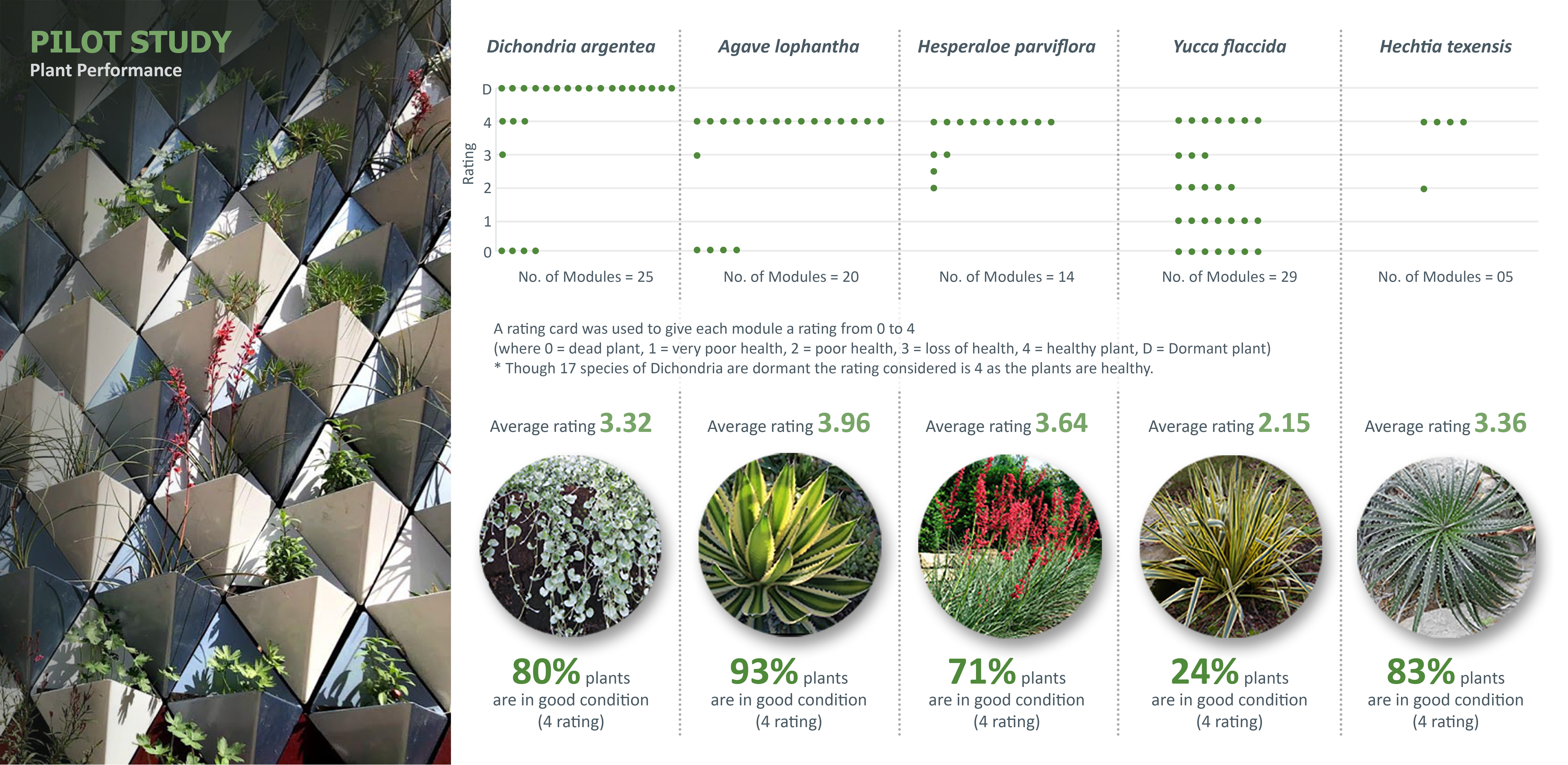

After the design phase, we started building the modules in Winter and Spring 2018. The galvanized sheet metal sheet was cut according to the design using a waterjet machine. We ensured a minimum wastage of scrap metal while cutting. After getting the cut modules, they were folded to form two components and riveted together. All the modules were then painted using a similar car painting process to get the desired color. A pilot study was done to evaluate the performance of the selected plants in our custom living wall system. One-third of the wall was planted with plants like Dichondria argentea, Agave lophantha, Hesperaloe parviflora, Hechtia texensis and Yucaa faccisa ‘color guard’ in Summer 2018. The irrigation was set to provide 1.16 gal per week. After a few months, we did a performance analysis of these plants. Each plant was rated from zero to four (where 0 = dead plant, 1 = very poor health, 2 = poor health, 3 = loss of health and 4 = healthy plant). Dichondria argentea had 80% of its plant in good condition (4 rating), Agave lophantha had 93%, Hesperaloe parviflora 71%, Yucaa faccisa 21% and Hechtia texensis 83%. After analyzing and making conclusions from the performance mapping, additional plants were selected to add pollinator species, and were implemented during the spring of 2019. New plants filled the whole wall and replaced a few not doing well planted in 2018. We also compared the custom living wall with two of the market-base systems based on soil volume, plant canopy space and water delivery methods. Our analysis demonstrates that the living wall resolved the prior issues the design set out to accomplish, as were we able to select larger vegetation compared to the limitations of market-based products.

This design-build project is a result of successful collaboration between three main entities. Firstly, the automobile industry which supplied the materials free of cost, secondly, the core design team of professors and graduate students in landscape architecture and architecture programs, and thirdly, the workforce of graduate and undergraduate students and teams at the fabrication lab who contributed in bringing the design concepts to reality. This unique idea of a custom living wall system has great potential to demonstrate a circular economy for living walls. It is cost-effective and environmentally sensitive as it utilizes waste sheet metal. It can essentially create opportunities for research and design for the incoming students in the landscape architecture and architecture programs. They can get a hands-on experience in understanding how a living wall system works and the factors playing a key role in design of modules and structural systems. Their academic products can be marketed commercially to promote the integration of the living wall systems in infrastructural development and making this project and the processes involved cyclical. The custom living wall system has proved to be sustainable, reduces heat reflectivity to cool the microclimate, creates an aesthetic appeal, is easy to maintain, attracts pollinator insects and butterflies and functions well compared to few other living walls in Texas.