Urban Aquatic Health: Integrating New Technologies and Resiliency into Floating Wetlands

It’s a template for how to do waterfront design.

Awards Jury

-

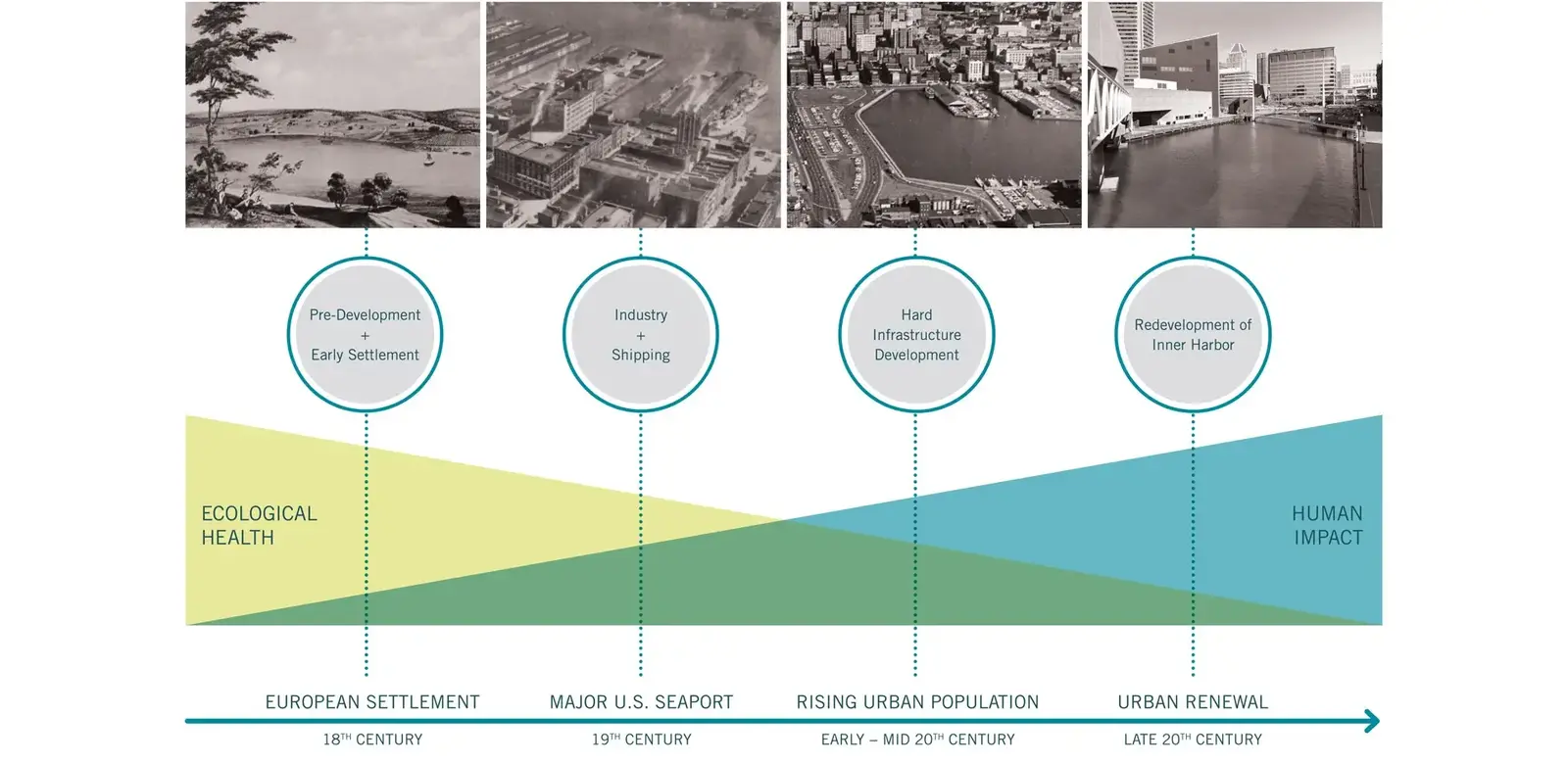

The National Aquarium in Baltimore, Maryland sits on a typical post-industrial urban waterfront. Their unique position as global actors and habitat experts makes them well positioned to be an agent of change for urban water quality. With an ultimate goal of transforming their campus into a living lab, the Aquarium teamed with designers, engineers, and researchers to investigate new technologies to produce a more sustainable and high-performing floating wetland.

-

The National Aquarium's mission is to inspire the conservation of the world's aquatic treasures. With its prime location on Baltimore's Inner Harbor, the Aquarium seeks to localize this mission by implementing a new campus landscape focused on highlighting important habitats of the Chesapeake Bay, including the introduction of a uniquely resilient engineered floating tidal marsh ecosystem. This habitat will support native marsh grasses and important microhabitats vital to many of the Chesapeake Bay's estuarine organisms. The tidal floating wetland is expected to improve water quality through the natural benefits of the wetlands combined with engineered solutions.

The first step to realizing this campus-wide initiative is confirming that the proposed design solutions will make a meaningful change to water conditions. Using a smaller-scale prototype as its basis for this research, the National Aquarium team is researching interventions, including their dimensional, spatial, and anchoring details, as well as developing performance criteria to fully investigate methods of improving biodiversity, transforming water quality and demanding resiliency. The knowledge gained by this research will ultimately inform future campus wide solutions.

The prototype research evaluates the following criteria:

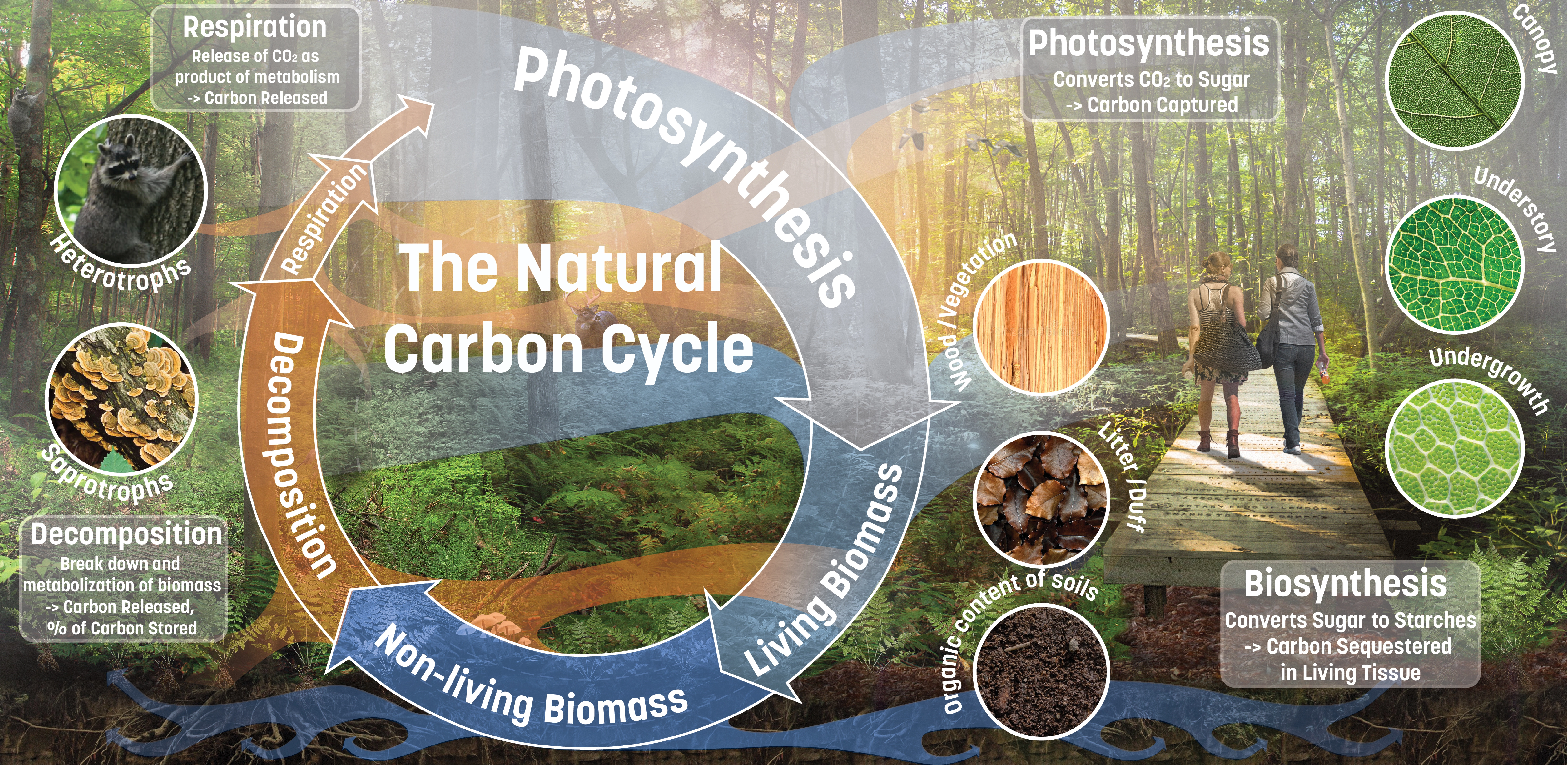

- Habitat Creation - The ability to adequately establish sustainable microhabitats present within a typical salt marsh and dramatically improve biodiversity within its urban context.

- Wetland Resiliency - Elevate the life span from a conventional floating wetland systems to allow for adjustable buoyancy to mitigate added weight from biomass accumulation.

- Water Quality - Integrate continuous aeration through a network of air diffusers to assist in regulating dissolved oxygen and water movement within the shallow canal and function as a refuge for aquatic organisms during low dissolved oxygen (D.O.) events.

Habitat Creation

The wetlands consist of media set at different elevations, relative to the water surface to mimic the microhabitats observed in tidal marshes of the Chesapeake Bay estuary. The wetlands are designed to rest at a predetermined elevation in the water column to support a variety of habitat conditions, both above and below the water surface. A channel between wetland areas mimics a small tidal canal.

The structured floating wetland media is custom fabricated with the layers +/- 3" from waterline embedded with buoyancy foam integrated into the media. Media layers outside the stated threshold are continuous solid material. The overall service life of the structured floating wetlands is a function of the structural platform. Increased longevity from UV degradation will be achieved with the application of a cementitious bonding layer.

Layered unwoven polyethelene terepthalate (PET media) is utilized as wetland panels (5 by 12 foot maximum) are fabricated by layering 1.5-inch PET media to create topographic microhabitats. Modules have internal foam for reserve static buoyancy.

Research questions:

- How might the buoyancy foam impact the growth/spreading of plantings?

- What is the best surface coatings/cover material for durability and ability to retain sand layer in the shallow canal?

- What range of water depths are intertidal species willing to utilize without tidal fluctuations?

- At what elevations do the high marsh communities have the highest survival rates?

- With oyster communities being a keystone species, do clusters of oysters in strategic places (canal openings) further entice species to the structure?

Wetland Resiliency (tethering, structure, buoyancy)

The floating wetland tethering and anchorage system must be capable of resisting anticipated wind, wave, and current loads, while allowing the wetland to effortlessly respond with daily tidal fluctuation. The prototype requires designed floatation devices to maintain appropriate levels and stability when subject to environmental or personnel loads and are constrained to have very little reserve buoyancy (freeboard).

The highest elevations of the marsh levels extend a mere 6 inches above water and the medium is porous and almost entirely void space. The lack of reserve buoyancy makes the wetland less stable than most conventional floating structures (e.g., floating docks, barges, etc.). This inherent lack of stability leads to a more sensitive floating structure that has separate reserve, static, and dynamic buoyancy systems.

Pontoon Buoyancy Control System - Each pontoon is outfitted with a pneumatic air hose at the top and ballast water hose at the bottom. The hoses run to the perimeter of the wetland where an operator can open and close valves as necessary to push air into the pontoon or bleed air outwards, thereby controlling the water level in the pontoon and the floating elevation of the wetland.

Reserve Buoyancy System in PET Media - The reserve buoyancy system within the PET layer is one of the most difficult and sensitive portions of the buoyancy design. As buoyancy is directly related to the weight of water displaced, the wetland has very little buoyancy in reserve to counteract the added weight of maintenance workers and waves. In response, at contour locations above the waterline, cavities within the PET are filled with spray-applied closed cell marine foam.

Static Buoyancy System and Ballast Weights - A portion of the HDPE pontoons were originally planned to be filled with closed cell marine foam, and provide an unchanging buoyant force, referred to as the "static buoyancy system." This foam fill and static buoyant force are calibrated to match the weight of the wetland's structural components, PET, and plantings. As insurance that the prototype does not float too high up in the water, attachment points for ballast weights are provided on the HDPE pipes. The ballast weights are also required to simulate the effect of accumulated marine growth to test the pontoon buoyancy system.

Research questions:

1. What is the durability and longevity of pontoon ballast control system (i.e., pipes, valves, controls)?

2. How sensitive is the pontoon system and frequency needed to re-ballast pontoons?

3. What are the buoyant properties of plantings?

Only foam within PET and PET with off-the-shelf properties are currently considered in reserve buoyancy calculations. Any additional volume displacement within PET layers will increase wetland stability.

4. What are the effect of marine growth colonization and decrease of volumetric void space in PET over time?

Water Quality (Aeration)

The prototype aeration system allows for testing of different materials and aeration technologies to increase dissolved oxygen levels within the water body to ensure the survival of fish, oysters and other aquatic organisms during low-oxygen events such as algae blooms and turn-over periods. The system utilizes an onshore blower, air delivery piping (on shore and floating laterals), and fine-bubble membrane diffuser assemblies that are suspended from the floating wetland. The prototype aeration system is adjustable and operated on an as-needed basis. The system function is informed by dissolved oxygen (D.O.) measurements from probes (sondes) within the canal or by manual operation. The system utilizes an onshore blower, air delivery piping (on shore and floating laterals), and fine-bubble membrane diffuser assemblies that are suspended from the air piping system.

A goal of the aeration system is to raise dissolved oxygen levels in the top 6-8 ft of water column in the areas around the floating wetland prototype. The system includes an onshore blower that is installed in a location with adequate soundproofing, maintenance access and that provides for efficient distribution of the air into the air delivery piping network.

Performance Requirements:

Service Life- Equipment, piping, accessories, appurtenances and diffusers are constructed of materials suitable for use in an estuarine/marine environment. Membranes use PTFE to resist fouling. The aeration system operates 24/7 to monitor treatment levels around the prototype. The system is manually controlled and may require manual adjustments as needed.

Research questions:

1. How will enhancing dissolved oxygen levels and water movement along the wetland perimeter affect aquatic life in the canal and within the wetland structure?

2. At what rate will the airlift assembly become clogged (biofoul)?

3. How many diffusers will it take to make a sizable impact in aquatic activity?

4. What is the optimal spacing of aerator? Determine by measure D.O. at various depths and distances.

-

Lead Designer

- Ayers Saint Gross

Landscape Architect: Ayers Saint Gross

- Jonathan Ceci, ASLA, Principal (former)

- Adam Ravestein, ASLA, Landscape Architect

- Amelle Schultz, ASLA, Project Manager

- Shelly Drees, ASLA, Designer

- Joseph Kim, Assoc. ASLA, Designer

Client Project Team:

- Jacqueline Bershad, RA

- Jack Cover

- Charmaine Dahlenburg

- Paul Valiquette

Client Interpretion Team:

- Jenny-Sayre Ramberg, Director of Exhibit Planning & Design

- Robin Faitoute, Manager of Exhibit Development

Executive Advisory Team:

- John Racanelli, President/Chief Executive Officer (National Aquarium)

- Dale Schmidt, EVP Chief Operating Officer (National Aquarium)

Science Advisory Team:

- Dr. Eric Schott, Assistant Research Professor, University of Maryland Center for Environmental Science (UMCES) at the Institute of Marine And Environmental Technology (IMET)

- Dr. Tsvetan Bachvaroff, Assistant Research Professor, UMCES at IMET

- Adam Frederick, Assistant Director for Education, Maryland Sea Grant at IMET

Ecological Engineer: Biohabitats

- Chris Streb, P.E.

- Justin Park, ASLA

- Erin English, P.E.

Marine/Civil/Structural Engineering: McLaren Engineering Group

- David W. McLaren, P.E.

- Matthew McCarty, P.E., S.E.

- Stephanie J. Richmond, P.E.

M-E-P Engineering: Kovacs, Whitney & Associates Inc.

- William B. Whitney, IV, P.E.

Strategic Master Plan Consultants: Studio Gang Architects

- Jeanne Gang

- Mark Schendel

- Juliane Wolf

- Magda Wala

- Claire Cahan

Construction/Fabrication Team:

- The Whiting-Turner Contracting Company (CM)

- Coastal Marine Sciences

- Floating Wetland Solutions

- Structural Fiberglass Incorporated

- ISCO Industries

.webp?language=en-US)